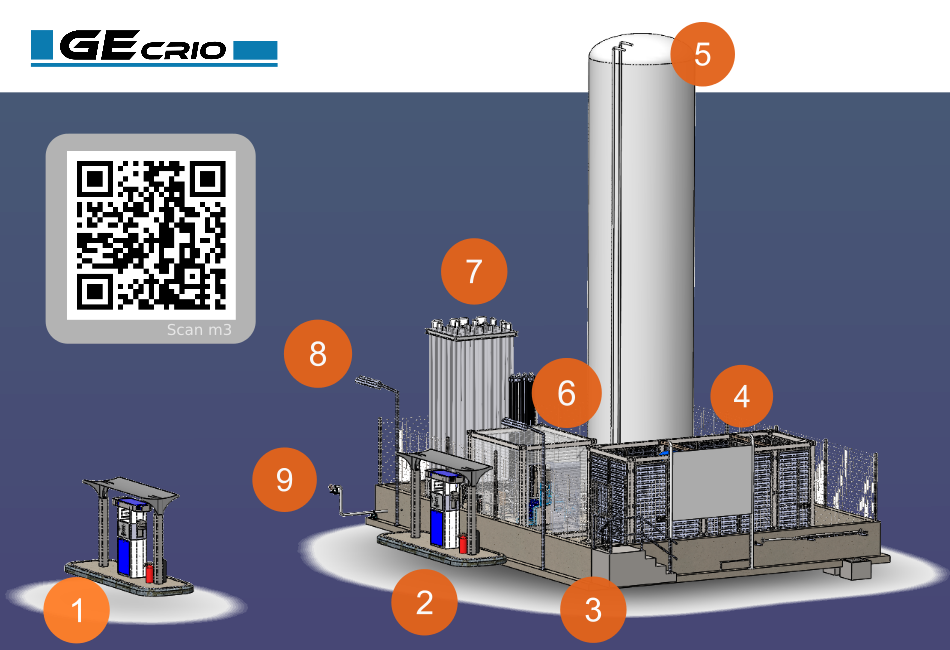

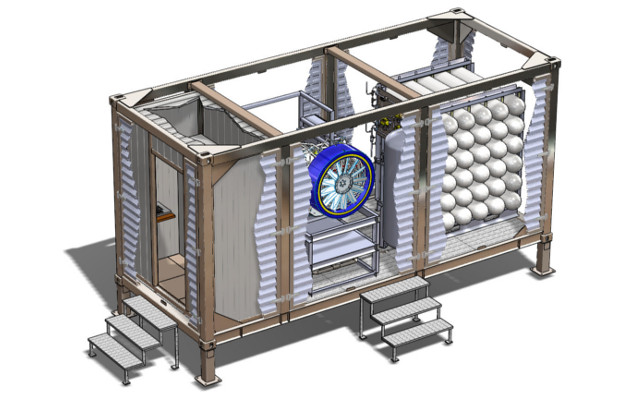

Modular

Normalización de equipos y capacidades. Plataformas contenedor estándar 20-40 pies

Express

Máximo 3 días para montaje y puesta en marcha !!! Soluciones en skid, plazo aún menor

Plug&Play

Soluciones probadas desde fábrica. Listas para usar

Todo en Uno

Sistemas con alto grado de integración, listos para ser usados en situaciones de emergencia, reparación, proyectos pilotos